COLD WEATHER APPLICATION GUIDELINES 2025-2026

Cold temperatures change the physical properties of adhesives, sealants, and primers, and alter the handling characteristics of roofing membranes due to increased rigidity. The information in this Bulletin is intended to help installers successfully apply GenFlex materials in cold weather. GenFlex recommends cold weather application procedures be used when ambient and substrate conditions fall below 40 °F (4 °C). Refer to applicable Product Data Sheets (PDS) for specific storage, handling, and application recommendations.

ADHESIVES, SEALANTS, AND PRIMERS

STORAGE

- Store all adhesives, sealants, and primers between 60 °F (16 °C) and 80 °F (27 °C) until just prior to application to ensure proper mixing and dispensing of the products, and to promote appropriate application rates.

- If the properties and application characteristics of the materials begin to change during cold weather application, restore them to room temperature before continuing. Materials stored

below 60 °F (16 °C) must be brought to room temperature, thoroughly mixed, and examined to verify proper consistency (no marbling or separation of components) prior to application.

MIXING & DISPENSING

When liquid materials are cold, their viscosity increases, and may cause solvents and solids to separate. This separation can make mixing and dispensing difficult. To minimize the potential for

materials cooling on the roof before application, follow these additional guidelines:

- Only bring materials from warm storage to the roof 1 to 4 hours prior to application, or as necessary to ensure materials are close to 60 °F (16 °C) when dispensed.

- Always thoroughly mix adhesives, and primers to a smooth, uniform state before and during use. Follow mixing instructions provided with each product. Do not use mixing equipment that could generate a spark, which could ignite flammable material.

- In extreme conditions, it may be necessary during application to rotate material between a hot box or warm storage area and the roof to maintain the appropriate application temperature.

APPLICATION

- Drying times depend on ambient conditions. Cool and overcast conditions lengthen open times (“tack times”), while sunny and dry conditions shorten open times. Expect and plan for longer

open times in colder weather prior to adhering insulation or membrane. - Blisters may occur when membranes are installed using solvent-based adhesives or primers that have not sufficiently dried. Conduct “touch-push” tests in areas with the heaviest application

of adhesive or primer, using a clean finger and adequate pressure to verify solvents have flashed off. A false reading may be given if a “touch-push” test is not performed properly in cold weather. Additionally, some products’ readiness may not be verified by a touch-push test but should be determined instead by the specific open times for those products. Refer to the GenFlex website for current PDS and application instructions for each product. - Follow all local air quality management requirements when installing products containing Volatile Organic Compounds (VOCs).

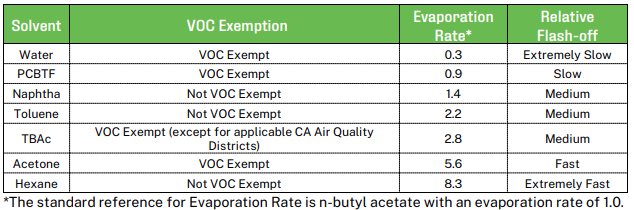

SOLVENT EVAPORATION RATES

The table below shows various flash-off times associated with solvent components of GenFlex adhesives, sealants, and primers. Our products may contain one or more of the solvents listed below.

Because the ratios of solvents in each product vary, a definitive flash-off time for each product cannot be assigned. Reference the specific product’s Safety Data Sheet (SDS) for chemical components and compare that information to the table below for an indication of relative flash-off efficiency. Ambient conditions will affect flash-off times, but the effects are proportional.

ADHESIVE “BLUSHING” (CONDENSATION)

- Blushing occurs when the evaporative cooling of the material during dry time lowers the surface temperature at or below the dew point, resulting in condensation on adhesive and primer films. This condensation prevents proper adhesion. Discontinue application immediately if blushing occurs.

- The use of adhesives and primers should be closely monitored for blushing when the ambient temperature is close to the dew point. The gap between the ambient temperature and the dew

point is typically narrower in early morning and late afternoon, so midday is often the optimal time to use adhesives and primers when applying GenFlex products in cold weather conditions. Greater exposure to sunlight at any time of day decreases the risk of blushing.

ONE STEP INSULATION ADHESIVE

- Where product specifications allow, use GenFlex One Step Insulation Adhesive when ambient and substrate temperatures are at least 20 °F (-7 °C) and rising. Ensure all surfaces to receive

One Step Insulation Adhesive are completely clean, dry, and free of frost. - Store One Step Insulation Adhesive and dispensing equipment between 60 °F to 80 °F (16 °C to 27 °C) until just prior to use. Return any unused One Step Insulation Adhesive cartridges and

dispensing equipment to warm storage if not used within four hours and allow product and equipment to return to 60 °F to 80 °F (16 °C to 27 °C) until just prior to use. See PDS 812 for full storage, handling, and application requirements.

BARRIERS

VAPOR BARRIER

- Vapor Shield Membrane may be applied when substrate and ambient temperatures are 25 °F (-4 °C) or higher provided the Vapor Shield has been stored between

50 °F to 100 °F (10 °C to 38 °C) prior to application. - Refer to the intended primer’s PDS for storage and application instructions, and limitations, if applicable.

ROOFING MEMBRANES AND FLASHINGS

MEMBRANE PREPARATION

- Store roofing membranes in a clean, dry location out of direct sunlight, and away from sources of punctures or other physical damage.

- Prior to installation, unroll membranes and allow them to relax for 30 to 60 minutes.

- Folded membrane panels become more difficult to relax and install in cold weather, especially with adhered systems. The use of no-fold panels in cold weather is highly recommended.

EZ TPO INSTALLATION

- EZ TPO membranes become more rigid in cold temperatures. To help EZ TPO membranes relax (including all standard, Peel & Stick, and EZ Fleece Backed TPO membranes), early on

the day of installation, remove the outer wrapping and leave the roll in the sunlight as long as possible. This will enable the darker bottom ply of the EZ TPO membrane to absorb as much

heat as possible and increase the membrane’s flexibility. - To ensure seams are properly welded when using an automatic welder, it is critical that test welds are done:

- At daily start-up

- When ambient conditions change

- When welding stops for a significant period of time (e.g., lunch breaks)

- When using a hand welder, test welds should be performed on scrap membrane or unsupported flashing material to ensure the operator is using the proper technique and temperature setting.

QUICK JET ADHESIVE

- Quick Jet Adhesive should be stored to maintain the desired product temperature of 70 °F (21 °C).

- Apply only when substrate and ambient temperatures are 25 °F (-4 °C) and rising.

- Do not apply when wind speeds are 15 mph or higher.

EZ EPDM PEEL & STICK™ and EZ TPO PEEL & STICK™ MEMBRANE INSTALLATION

- Store EZ EPDM Peel & Stick and EZ TPO Peel & Stick membrane in a clean, dry location, and keep dry prior to installation.

- EZ EPDM Peel & Stick and EZ TPO Peel & Stick may be installed when ambient and substrate temperatures exceed 20 °F (-7 °C).

EZ TPO INVISIWELD™ APPLICATIONS

- The minimum safe application temperature for induction welding of the EZ TPO membrane to EZ TPO InvisiWeld or EZ TPO InvisiWeld-S plates is 0 °F (-18 °C).

- Before induction welding with the appropriate tool, ensure there is no moisture or condensation present on the top surface of the plate or on the bottom surface of the EZ TPO

membrane. Moisture will affect the ability of the induction tool to weld and may result in partial or incomplete welds. - Always follow the induction tool manufacturer’s guidelines for calibration and use of the tool in cold temperatures. In general, the tools must be calibrated regularly or in real time and

ON-SITE, i.e., using materials (membrane and plates) that are at the same temperature conditions as the jobsite materials.

EPDM FLASHING and TAPE PRODUCTS (PEEL & STICK) INSTALLATION

- Uncured EPDM flashing and tape products (both standard and FlexWhite) are designed to be formable, but cold weather may require supplemental warming with a heat gun.

- Ambient conditions (sunlight, wind, and temperature) and flashing color will determine the need for supplemental heat. Typically, temperatures below 60 °F (16 °C) may require the use of additional heat to ensure the formability of uncured flashing products.

- Keep heat guns and other potential ignition sources away from cleaners, primers, adhesives, or other flammable materials.

SBS AND APP INSTALLATION

- Store SBS and APP modified bitumen rolls between 50 °F and 100 °F (10 °C and 38 °C) and install only when ambient and substrate temperatures are 40 °F (4 °C) and rising. Where project

characteristics allow, torch-applied membranes are strongly recommended for cold weather applications. - Materials must be used within 4 hours of removal from a heated storage area. Materials that are not used within 4 hours must be returned to a heated storage area until they return to a temperature between 50 °F to 100 °F (10 °C and 38 °C), which typically takes 24 hours.

- Hot Asphalt

- Cold substrates can rapidly cool mopped asphalt. Asphalt cools and thickens more quickly at low temperatures, which may cause application rates to be less uniform.

- All handling equipment should be insulated to minimize drops in asphalt temperature prior to or during application.

- Maintain a temperature in the kettle within the asphalt manufacturer's published equiviscous temperature (EVT) range, but hot enough to ensure a minimum application temperature at the mopping point of 420 °F (216 °C).

- Do not overheat asphalt to compensate for cold weather conditions or allow the temperature to exceed the asphalt manufacturer's EVT or its flash point.

MULTI-PURPOSE MB COLD ADHESIVE AND FLASHING CEMENT

- Store Multi-Purpose MB Cold Adhesive and Multi-Purpose MB Flashing Cement between 60 °F to 80 °F (16 °C and 27 °C) in their original, unopened containers.

- Multi-Purpose MB Cold Adhesive is best applied with a heated spray rig in cold weather. Squeegeeapplied Cold Adhesive is not recommended during cold weather.

- Multi-Purpose MB Cold Adhesive and Multi-Purpose MB Flashing Cement should only be used when ambient and substrate temperatures are 40 °F (4 °C) and rising.

For further information or assistance, please contact Amrize Technical Services at 800-443-4272 or visit the GenFlex website at www.genflex.com.